Product Details:

Payment & Shipping Terms:

|

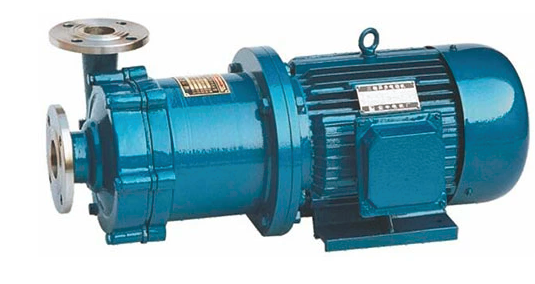

| Product Name: | Magnetic Pump | Model: | CQ |

|---|---|---|---|

| Power: | Electric | Packing: | Standard Wooden Case Packing |

| Voltage: | 220V/380V/400v-480v | Application: | Acid/alkali/oil/leaky/inflammable Expensive Liquid |

| High Light: | sulfuric acid transfer pump,centrifugal transfer pump |

||

CQ series resistance to corrosion magnetic drive pump for transfer acid/alkali/oil/leaky/inflammable expensive liquid

CQ series resistance to corrosion magnetic drive pump for transfer acid/alkali/oil/leaky/inflammable expensive liquid (referred to as magnetic pump) is a new product that uses the working principle of permanent magnet coupling for centrifugal pump. It has reasonable design, advanced technology, full sealing, no leakage and corrosion resistance. Its performance has reached abroad. The advanced level of similar products. The magnetic pump replaces the dynamic seal with a static seal, so that the over-current component of the pump is completely sealed, completely solving the disadvantages of running, escaping and dripping which cannot be avoided by the mechanical seal of other pumps. The magnetic pump is made of corrosion-resistant and high-strength engineering plastic. Steel jade ceramics and stainless steel are used as manufacturing materials, so it has good corrosion resistance and can protect the transport medium from contamination.

The magnetic pump has compact structure, beautiful appearance, small volume, low noise, reliable operation and convenient use and maintenance. Can be widely used in chemical, pharmaceutical, petroleum, electroplating, food, film photofinishing, scientific research institutions, defense industry and other units to pump acid, lye, oil, rare precious liquids, venom, volatile liquids, and circulating water equipment, Filter kit. Especially for the pumping of leaky, flammable and explosive liquids, it is more ideal to use this pump.

CQ series resistance to corrosion magnetic drive pump for transfer acid/alkali/oil/leaky/inflammable expensive liquid installation and use

1. The magnetic pump should be installed horizontally and should not be erected. The plastic pump body must not bear the weight of the pipeline. For the special requirements of vertical installation, the motor must face upwards.

2. When the suction liquid level is higher than the pump shaft line, open the suction pipe valve before starting. If the suction liquid level is lower than the pump shaft line, the pipe should be equipped with a bottom valve.

3. The pump should be inspected before use. The motor blades should be flexible to rotate, no jamming, no abnormal sound, and the fasteners should be fastened.

4. Check if the motor rotation direction is consistent with the magnetic pump steering mark.

5. After the motor starts, slowly open the discharge valve. After the pump enters the normal working state, adjust the discharge valve to the required opening degree.

6. Before the pump stops working, close the discharge valve and close the suction pipe valve.

CQ series resistance to corrosion magnetic drive pump for transfer acid/alkali/oil/leaky/inflammable expensive liquid use precautions

1. Since the cooling and lubrication of the magnetic pump bearing is based on the medium to be transported, it is absolutely forbidden to perform the air-to-air transfer, and at the same time avoid the time-and-load operation caused by the power failure after the start of the work.

2. If the solid medium is contained in the medium to be transported, a filter should be added to the pump inlet: if it contains ferromagnetic particles, a magnetic filter is required.

3. The ambient temperature of the pump should be less than 40 °C during use, and the temperature rise of the motor should not exceed 75 °C.

4. The medium to be transported and its temperature should be within the allowable range of the pump (see attached table for details). The working temperature of the engineering plastic pump is <60 °C, the use temperature of the metal pump is <100 °C, the suction pressure is no more than 0.2mpa, the working pressure is 1.6mpa, the density is not more than 1600kg/m3, and the particle size is not more than 30×10-6m2/s. A liquid that does not contain hard particles and fibers.

5. For the medium which is easy to precipitate and crystallize, the medium should be cleaned in time after use, and the liquid in the pump should be drained. 6. After the magnetic pump is operated for 500 hours, the wear of the bearing and the end moving ring should be dismantled. If the clearance between the bearing and the bushing is greater than 0.5~1mm and the impeller axially moves 1.5~2mm, the bearing and axial movement should be replaced. ring.

| PH Value of slurry: 2.5-13 | Slurry temperature ≤ 65ºC | X type frame,space saving |

| Large capacity | High head | High efficiency |

| Wear resistance | Corrosion resistance | Energy saving |

| Wide flow range | Stable performance | Heavy duty |

| Little noise | Low vibration | Long service life |

| Interchangeable parts | Reliable operation | High chrome alloy material |

| Oil lubrication | Clockwise from drive end | Intergrating mechanical seal |

CQ series resistance to corrosion magnetic drive pump for transfer acid/alkali/oil/leaky/inflammable expensive liquid Performance data

| Model | Inlet | Outlet | Head | Capacity | Power | Speed | Voltage |

Stainless steel |

| (mm) | (mm) | (m) | (L/min) | (KW) | (r/min) | (Phase) | ||

| 14CQ-5 | 14 | 10 | 5 | 20 | 0.18 | 2800 | 1ph/3ph | |

| 16CQ-8 | 16 | 12 | 8 | 30 | 0.18 | 2800 | 1ph/3ph | |

| 20CQ-12 | 20 | 12 | 12 | 50 | 0.37 | 2800 | 1ph/3ph | |

| 25CQ-15 | 25 | 20 | 15 | 110 | 1.1 | 2800 | 3phase | |

| 32CQ-15 | 32 | 25 | 15 | 110 | 1.1 | 2800 | 3phase | |

| 32CQ-25 | 32 | 25 | 25 | 90 | 1.1 | 2800 | 3phase | |

| 40CQ-20 | 40 | 32 | 20 | 180 | 2.2 | 2800 | 3phase | |

| 40CQ-32 | 40 | 32 | 32 | 200 | 4 | 2800 | 3phase | |

| 50CQ-25 | 50 | 40 | 25 | 240 | 4 | 2800 | 3phase | |

| 50CQ-32 | 50 | 40 | 32 | 220 | 4 | 2800 | 3phase | |

| 50CQ-50 | 50 | 32 | 50 | 130 | 5.5 | 2800 | 3phase | |

| 65CQ-25 | 65 | 50 | 25 | 280 | 5.5 | 2800 | 3phase | |

| 65CQ-32 | 65 | 50 | 32 | 450 | 5.5/7.5 | 2800 | 3phase | |

| 80CQ-32 | 80 | 65 | 32 | 850 | 11 | 2800 | 3phase | |

| 80CQ-50 | 80 | 65 | 50 | 850 | 15 | 2800 | 3phase | |

| 100CQ-35 | 100 | 80 | 35 | 1000 | 15 | 2800 | 3phase | |

| 100CQ-50 | 100 | 80 | 50 | 1000 | 18.5 | 2800 | 3phase | |

| 125CQ-32 | 125 | 100 | 32 | 1700 | 22 | 2800 | 3phase | |

| 125CQ-32 | 125 | 100 | 32 | 2500 | 30 | 1450 | 3phase | |

| 150CQ-25 | 150 | 125 | 25 | 3350 | 30 | 1450 | 3phase |

Contact Person: Sarah

Tel: 008613676018543