Product Details:

Payment & Shipping Terms:

|

| Product Name: | Screw Pump | Model: | 3G Screw Pump |

|---|---|---|---|

| Theory: | Screw Pump | Application: | Lubricating Oil Mineral Oil Pump |

| Driver: | Electric Motor, Diesel Motor | Warranty: | 12 Month |

| High Light: | positive displacement pump,3 screw pump |

||

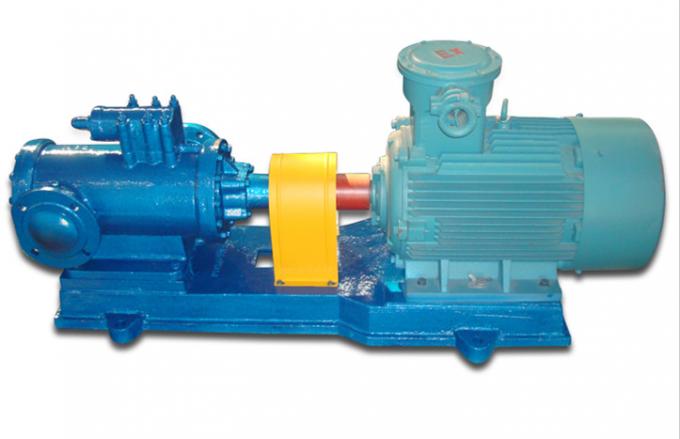

3G Series Marine Horizontal Diesel Three Screw Pump Positive Displacement Rotary Pump Lubricating oil Mineral oil Pump

Brief introduction

1. 3G high viscosity three screw pump high pressure triple Ignition oil pump is a kind of positive displacement rotary pump with the properly meshing in pump block.

2. The rotary screws could push the medium closed-in to outlet continuously & equably.

3. Pump could provide stable pressure to system and pump non-corrosive oil or lubricated liquid that similar to oil. It's with small pressure fluctuation, stable capacity, reliable running, high revolving speed, low noise, high efficiency, long service life & strong self-suction ability.

4. The viscosity of liquid should be 2500C.S.T, and temperature should be ≤200°C(392°F)-ordinary type or 350°C(662°F)-heat insulation type.

5. The high viscosity medium can be pumped by heating of double jacket type (which could lower viscosity). Pump is with double jacket casing which can be heated by hot steam, thermal oil, etc to reduce the viscosity of fluids with easy solidification.

Product application:

Three screw pumps can be used in the transformation of any lubricating liquid without any caustic impurity and the liquid that may not chemically erode the component of the pumps. For example, lubricating oil, mineral oil, synthetic hydraulic fluid and natural oil can be transferred by them. And other special lubricating medium such as light fuel, normal fuel oil, coal oil, high-temperature pitch, viscose, emulsion and resin can also be transferred by three screw pump.

Product details:

| Working Principle: | Three Screw (One main, two driven screws) |

| Main applications: | Heavy Oil, bitumen, etc |

| Driver: | Electric motor, diesel motor. |

| Power Specs: | 220/380/415V 3phase;50hz/60hz |

| Max.permissible fluid temperature: | 200°C(392°F)/350°C(662°F),Heat insulation |

| Type of : | Flange, Thread, Quick Coupled. |

| Installation position: | Horizontal |

| Casing/Inner parts material: | Cast iron, Stainless Steel/Cast iron, Stainless steel, Bronze |

| Shaft seal type: | Mechanical seal |

| Maximum viscosity: | 2.5×103C.S.T / 3×106C.S.T(Heat insulation) |

| Maximum drive rating: | 55KW(75HP) |

| Maximum caliber: | 200mm(8inch)-in/150mm(6inch)-out |

| Maximum discharge-side pressure: | 2.5MPa(25bar) |

| Flow rate range: | 2.4-126m3/h(10.56-554.4US.GPM) |

Performance data

|

Model |

Type |

Motor |

Pressure (Mpa) |

Flow(m3/h) | Speed(r/min) | ||

| Power(KW) | Type | m3/h | L/min | r/min | |||

|

001 |

25×4-46 |

0.75 | Y802-4 | 1 | 0.8 | 13 | 1450 |

| 1.5 | Y90L-4 | 2.5 | 0.6 | 10 | |||

| 1.5 | Y9OS-2 | 1 | 2 | 33 | 2900 | ||

| 3 | Y100L-2 | 2.5 | 1.6 | 26 | |||

|

002 |

30×4-46 |

1.1 | Y9OS-4 | 1 | 1.6 | 26 | 1450 |

| 2.2 | Y100L1-4 | 2.5 | 1.2 | 20 | |||

| 2.2 | Y90L-2 | 1 | 3.6 | 60 | 2900 | ||

| 4 | Y112M-2 | 2.5 | 3.2 | 53 | |||

|

003 |

36×4-46 |

2.2 | Y100L1-4 | 1 | 2.8 | 46 | 1450 |

| 4 | Y112M-4 | 2.5 | 2.4 | 40 | |||

| 4 | Y112M-2 | 1 | 6.5 | 108 | 2900 | ||

| 7.5 | Y132S2-2 | 2.5 | 6 | 100 | |||

|

004 |

42×4-46 |

4 | Y112M-4 | 1 | 4.8 | 80 | 1450 |

| 5.5 | Y132S1-4 | 2.5 | 4.2 | 70 | |||

| 5.5 | Y132S1-2 | 1 | 10.5 | 175 | 2900 | ||

| 15 | Y160M2-2 | 2.5 | 10 | 166 | |||

|

005 |

45×4-46 |

3 | Y100L2-4 | 1 | 6.3 | 106 | 1450 |

| 7.5 | Y132M-4 | 2.5 | 5.9 | 99 | |||

| 7.5 | Y132S2-2 | 1 | 13.5 | 225 | 2900 | ||

Contact Person: Sarah

Tel: 008613676018543