Product Details:

Payment & Shipping Terms:

|

| Product Name: | Multistage Centrifugal Pump | Stage: | Multistage |

|---|---|---|---|

| Material: | Cast Iron/stainless Steel | Colour: | Red/black |

| Application: | Fire Water | Warranty: | One Year |

| High Light: | multistage centrifugal water pump,boiler water circulating pump |

||

CDL/CDLF series vertical multistage centrifugal pump CCCF certified vertical multistage fire jockey pump

Brief Introduction

Multistage Centrifugal Pump CDL/CDLF is a kind of multi function product with wide application. It may transmit various mediums including water or industrial liquid and is suitable for different temperature, flow rate and range of pressure. Its typical application mainly includes the following aspects,

CDL/CDLF is a kind of multifunctional products. It can be used to convery various medium from tap water to industrial liquid at different temperature and with different flow rate and pressure. CDL type is applicable to conveying non-corrosive liquid, with CDLF is suitable for slightly corrosive liquid.

1. Water supply: Water filter and transport in waterworks, boosting of main pipeline, boosting in high-rise buildings.

2. Industrial boosting: Process flow water system, cleaning system, high-pressure washing system, fire fighting system.

3. Industrial liquid conveying: Cooling and air-conditioning system, boiler water supply and condensing system, machine-associated purpose, acids and alkali.

4. Water treatment: Ultrafiltration system, reverse osmosis system, distillation system, separator, swimming pool.

5. Irrigation: Farmland irrigation, spray irrigation, dripping irrigation.

Features:

1. Compact structure, this series Multistage Centrifugal Pumps are horizontal structure, motors and pumps assembled into one, beautiful appearance, small area, compared with the normal horizontal pump, the area reduce by 30%.

2. Multistage Centrifugal Pumps are balanced running, low noise, high components concentricity.

3. No leakage Multistage Centrifugal Pumps.

4. Convenient maintenance Multistage Centrifugal Pumps.

5. From the inlet direction of this series Multistage Centrifugal Pump, the outlet of the pump can be installed arbitrarily in straight up way.

Working condition:

1. The maximum working pressure of Multistage Centrifugal Pump system ≤1.6MPa, Multistage Centrifugal Pump inlet pressure + pump lift ≤1.6MPa , so when ordering please indicate the system working pressure. When the inlet pressure is greater than 0.4 MPa or the system working pressure is greater than 1.6MPa, please put forward when ordering , so that when manufacturing we can take appropriate measures in the pump flow portion and connection portion;

2. Applicable medium: solid insoluble matter volume content of the medium is no more than 0.1% of the unit volume, particle size is no more than 0.2mm, if the medium has fine particles, please indicate when ordering .

3. Ambient temperature doesn't exceed 40 centigrade, relative humidity is no more than 95%;

4. Thin, clean, non-flammable and non-explosive liquid containing no solid granules and fibers;

5. Liquid temperature: <70 °C;

6. Altitude: up to 800m.

Note:Special demands can be negotiated.

Structure:

1. The Multistage Centrifugal Pump for the vertical structure, import and export of the same caliber, and in the same center line, as the valve installed in the pipeline, compact appearance, small footprint, low construction inputs, such as with the shield It can be placed outdoors.

2. The impeller of Multistage Centrifugal Pump is mounted directly on the motor shaft extension, the short axial dimension, compact structure, reasonable configuration of pump and motor bearings, can effectively balance the radial and axial loads generated by operation of the pump, thus ensuring the smooth operation of the pump, vibration and low noise.

3. Seal with mechanical seal or a combination of mechanical of the Multistage Centrifugal Pump, using imported titanium alloy seal ring, medium and high temperature mechanical seal with carbide materials, wear-resistant seal, can effectively extend mechanical seal life.

4. Easy installation and maintenance, no need to open pipe road system, as long as remove the pump nut seat body out all the rotor components.

5. Flow and head requirements that need using Multistage Centrifugal Pumps in series and parallel operation according to the requirements.

6. Can use the vertical and horizontal pipeline pumps installed according to requirements of piping layout.

| Working Principle: | Centrifugal, Multistage |

| Main applications: | Water |

| Driver: | Electric motor |

| Power Specs: | 220V/380/415V 3phase; 220/240V 1phase; 50hz/60hz,etc |

| Max.permissible fluid temperature: | 80℃/120°C(hot water type) |

| Type of connection: | Flange connection |

| Installation position: | Vertical |

| Impeller/diffuser/inducer/shaft material: | Stainless steel 304 or 316 |

| Shaft seal type: | Mechanical seal |

| Maximum drive rating: | 110KW(150HP) |

| Maximum caliber: | 150mm(6inch) |

| Maximum dischrage-side pressure: | 2.55MPa(25.5bar) |

| Maximum head: | 255m(836.4ft) |

| Flow rate range: | 1-240m3/h(4.4-1056US.GPM) |

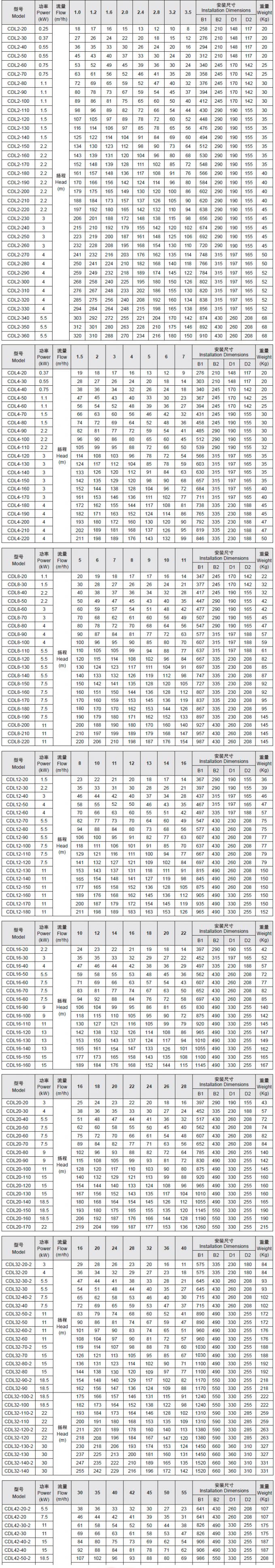

Technical data:

Contact Person: Sarah

Tel: 008613676018543