Product Details:

Payment & Shipping Terms:

|

| Product Name: | Air Operated Diaphragm Pump | Structure: | Diaphragm Pump |

|---|---|---|---|

| Usage: | Oil And Chemical | Material: | Cast Iron, Stainless Steel 304 316, Plastic |

| Diaphragm Material: | NBR, PTFE, Telfon | Warranty: | 1 Year Warranty(except Wearing Parts) |

| High Light: | double diaphragm pump,pneumatic diaphragm pump |

||

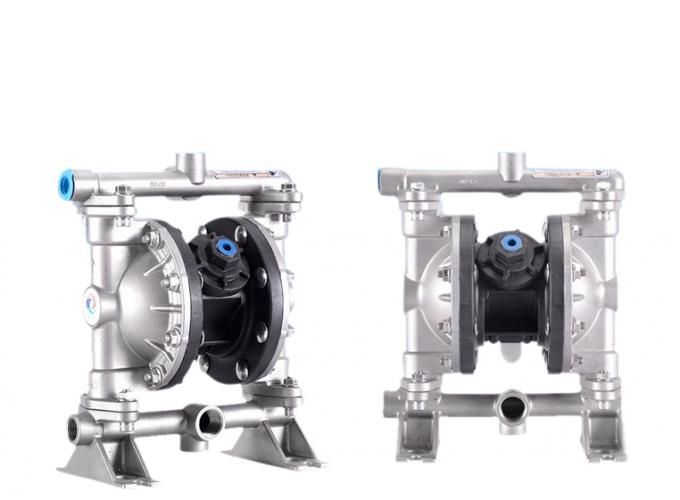

QBY series anti strong acid alkali chemical pneumatic pump air operated diaphragm pump

Brief introduction

1. QBY anti strong acid alkali chemical pneumatic pump air driven liquid pump is not only capable of exhausting the flow liquid , but also can convey some uneasy flowed medium, with the merits of self-priming pump, diving pump, shield pump, slurry pump and impurity pump etc.

Advantages:

1. No electricity. It's safe and reliable while in the flammable and explore places.

2. Pump has no rotary parts and bearing seals. The diaphragm will completely separate the exhausted medium and pump running parts, working medium. There’s no leakage, thus it doesn’t cause environmental pollution and human body safety dangerous while exhausting the toxin and flammable or corrosive medium.

3. It's convenient to use and reliable to work. This pump is simple in structure and easy to be installed and maintained.The medium conveyed doesn’t touch the matched pneumatic valve and coupling lever etc. While normal pumps’ performance will be decreased gradually because of the damages of driving parts.

4. This pump doesn’t need oil lubricant, even works in dry run.

Product application:

1. The pump transports various toxin, flammable, volatility strong acid, alkali and corrosive liquid etc.

2. The pump may suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops, syrup, paint, pigment, glue, adhesive, glazed slurries of tile, porcelain, brick, chinaware, grinding materials, corrosive agent, clean the oil dirt, wedge water, cement slurry and mortar etc.

3. It can be used as a front-step transmission device of the solid and liquid separation equipment.

Product details

| Working Principle: | Double Diaphragms, pneumatic |

| Main applications: | Oil, Water, Chemical, Foodstuff,etc. |

| Driver: | Air operated |

| Max.permissible fluid temperature: | 100°C(212°F) |

| Type of connection: | Flange, Thread, Quick Coupled. |

| Installation position: | Connect to compressor |

| Pump body mateiral: | CI, SS, AL, PP, PVDF, PTFE lined. |

| Diaphragm, ball, ball seat mateiral: | F46, PTFE, NBR, Santoprene, EPDM, etc |

| Maximum drive rating: | 7kgf/cm2 |

| Maximum caliber: | 100mm(4inch) |

| Maximum grain diameter: | 10mm(4inch) |

| Maximum dischrage-side pressure: | 6kgf/cm2 |

| Maximum head: | 50m(164ft) |

| Flow rate range: | 0.8-30m3/h(3.5-132US.GPM) |

Technical parameters:

| Model | Dia(mm) | Flow (m3/h) |

Head (m) |

Suction (m) |

Max Particle Size φ(mm) |

Air Pressure (kgf/cm2) |

| QBY-10 | 10 | 0.8 | 50 | 5 | 1 | 2-7 |

| QBY-15 | 15 | 1 | 50 | 5 | 1 | 2-7 |

| QBY-25 | 25 | 2.4 | 50 | 7 | 2.5 | 2-7 |

| QBY-40 | 40 | 8 | 50 | 7 | 4.5 | 2-7 |

| QBY-50 | 50 | 12 | 50 | 7 | 8 | 2-7 |

| QBY-65 | 65 | 16 | 50 | 7 | 8 | 2-7 |

| QBY-80 | 80 | 24 | 50 | 7 | 10 | 2-7 |

| QBY-100 | 100 | 30 | 50 | 7 | 10 | 2-7 |

Contact Person: Sarah

Tel: 008613676018543