Product Details:

Payment & Shipping Terms:

|

| Structure: | Single-stage Pump | Usage: | Water |

|---|---|---|---|

| Power: | Electric | Pressure: | High Pressure |

| Theory: | Centrifugal | Color: | Red/White/Blue/Green/Black |

| MOQ: | 1set | Delivery: | 3-7 Days |

| Package: | Plywood Case | Material: | Cast Iron Or Stainless Steel |

| High Light: | fire fighting water pump,motor driven centrifugal pump |

||

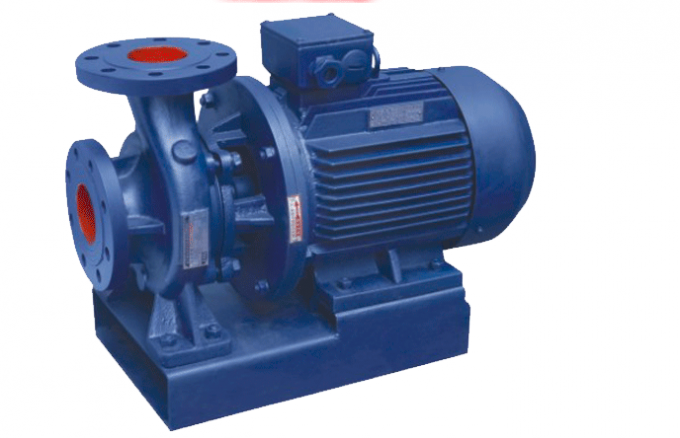

ISW series 1hp 2hp 3hp 5hp horizontal electric motor cast iron material centrifugal water pump

Product Description

ISW centrifugal water pump

Introduction:

ISW series 1hp 2hp 3hp 5hp horizontal electric motor cast iron material centrifugal water pump is with the merits of compact structure, small volume, stable running, easy to mount and maintain.

Widely used in industrial and cities’ water supply and drainage, high buildings’ booster water supply, gardens irrigation, fire-fighting booster, remote water supply, warming systems, circular booster of cold&hot water in bath rooms as well as in competitions of equipments.

Working Conditions:

1. Suction pressure ≤ 1.0MPa, the maximum pump system working pressure≤ 1.6MPa, the pump hydrostatic test pressure ≤ 2.5MPa.

2. Ambient temperature < 40 degrees, relative humidity≤ 40%.

3. Content of solid particles in the medium per unit volume does not exceed 0.1%, particle size < 0.2mm

Application:

ISW series 1hp 2hp 3hp 5hp horizontal electric motor cast iron material centrifugal water pump for conveying water or other liquids that physical and chemical properties similar to water, like industrial and urban water supply and drainage, high-rise building pressurized water, garden irrigation, fire boost, long-distance transport, HVAC refrigeration cycle, bathroom and heating equipment for pressurized water circulation, temperature < 80 degrees.

1. ISW ISG electric drum pumps is a high-effective energy-saving pump.

2. Stable running, low noise, high concentricity of components. Bearings of low noise are used for the motor, the impellers are of best dynamic and static balance, no vibration at running and the environment thus being improved.

3. No leakage. The shaft is mechanically sealed with carbide alloy wearable material, settling the serious leakage of the filling seal of a centrifugal pump and extending the duration and ensuring the operation place clean and tidy.

4. Widely used in industrial and cities’ water supply and drainage, high buildings’ booster water supply, garden's irrigation, fire-fighting booster, remote water supply, warming systems, circular booster of cold&hot water in bath rooms as well as in competitions of equipments.

5. The pump, according to the operation condition of the workshop, is vertical or horizontal, and also according to the requirements for the flow and stroke, mounted in parallel and/or in series to increase the needed flow and stroke.

6. The flow range is 1.1-2400m3/h and the stroke range is 8-160m and there are basic types, by-pass type, A B C cutting type etc. And per the different flow medium and temperature, IRG/IRGB/ISWR hot water pump, IHG/IHGB/ISWH series chemical pumps and YG/YGB/ISWB oil pumps.

Technical data

| Model | Capacity (m3/h) | Lift head (m) | Speed (r/min) | Motor (KW) | Inlet&Outlet Diameter (mm) |

| 15-80 |

1.1 1.5 2.0 |

8.5 8 7 |

2800 | 0.18 | 15 |

| 20-110 |

1.8 2.5 3.3 |

16 15 13.5 |

2800 | 0.37 | 20 |

| 20-160 |

1.8 2.5 3.3 |

33 32 30 |

2900 | 0.75 | 20 |

| 25-110 |

2.8 4 5.2 |

16 15 13.5 |

2900 | 0.55 | 25 |

| 25-125 |

2.8 4 5.2 |

20.6 20 18 |

2900 | 0.75 | 25 |

| 25-125A |

2.5 3.6 4.6 |

17 16 14.4 |

2900 | 0.55 | 25 |

| 25-160 |

2.8 4 5.2 |

33 32 30 |

2900 | 1.5 | 25 |

| 25-160A |

2.6 3.7 4.9 |

29 28 26 |

2900 | 1.1 | 25 |

| 32-100 | 4.5 | 12.5 | 2900 | 0.55 | 32 |

| 32-100(I) |

4.4 6.3 8.3 |

13.2 12.5 11.3 |

2900 | 0.75 | 32 |

| 32-125 |

3.5 5 6.5 |

22 20 18 |

2900 | 0.75 | 32 |

| 32-125A |

3.1 4.5 5.8 |

17.6 16 14.4 |

2900 | 0.55 | 32 |

| 32-160 | 6.5 | 32 | 2900 | 1.5 | 32 |

| 32-160A | 4 | 25 | 2900 | 1.1 | 32 |

| 32-160(I) |

4.4 6.3 8.3 |

33.2 32 30.2 |

2900 | 2.2 | 32 |

| 32-200 | 4.5 | 50 | 2900 | 3 | 32 |

| 32-200(I) |

4.4 6.3 8.3 |

50.5 50 48 |

2900 | 4 | 32 |

| 32-200A |

2.8 4 5.2 |

44.6 44 42.7 |

2900 | 2.2 | 32 |

| 40-100 |

4.4 6.3 8.3 |

13.2 12.5 11.3 |

2900 | 0.55 | 40 |

| 40-100A |

3.9 5.6 7.4 |

10.6 10 9 |

2900 | 0.37 | 40 |

| 40-125 |

4.4 6.3 8.3 |

21 20 18 |

2900 | 1.1 | 40 |

| 40-125A |

3.9 5.6 7.4 |

17.6 16 14.4 |

2900 | 0.75 | 40 |

| 40-160 |

4.4 6.3 8.3 |

33 32 30 |

2900 | 2.2 | 40 |

| 40-160A |

4.1 5.9 7.8 |

29 28 26.3 |

2900 | 1.5 | 40 |

| 40-160B |

3.8 5.5 7.2 |

25.5 24 22.5 |

2900 | 1.1 | 40 |

| 40-200 |

4.4 6.3 8.3 |

51 50 48 |

2900 | 4 | 40 |

| 40-200A |

4.1 5.9 7.8 |

45 44 42 |

2900 | 3 | 40 |

| 40-200B |

3.7 5.3 7.0 |

38 36 34.5 |

2900 | 2.2 | 40 |

| 40-250 |

4.4 6.3 8.3 |

82 80 74 |

2900 | 7.5 | 40 |

| 40-250A |

4.1 5.9 7.8 |

72 70 65 |

2900 | 5.5 | 40 |

| 40-250B |

3.8 5.5 7.0 |

61.5 60 56 |

2900 | 4 | 40 |

| 40-100(I) |

8.8 12.5 16.3 |

13.2 12.5 11.3 |

2900 | 1.1 | 40 |

| 40-100(I)A |

8 11 14.5 |

10.6 10 9 |

2900 | 0.75 | 40 |

| 40-125(I) |

8.8 12.5 16.3 |

21.2 20 17.8 |

2900 | 1.5 | 40 |

| 40-125(I)A |

8 11 14.5 |

17 16 14 |

2900 | 1.1 | 40 |

| 40-160(I) |

8.8 12.5 16.3 |

33 32 30 |

2900 | 3 | 40 |

| 40-160(I)A |

8.2 11.7 15.2 |

29 28 26 |

2900 | 2.2 | 40 |

| 40-160(I)B |

7.3 10.4 13.5 |

23 22 20.5 |

2900 | 1.5 | 40 |

| 40-200(I) |

8.8 12.5 16.3 |

51.2 50 48 |

2900 | 5.5 | 40 |

| 40-200(I)A |

8.3 11.7 15.3 |

45.0 44 42 |

2900 | 4 | 40 |

| 40-200(I)B |

7.5 10.6 13.8 |

37 36 34 |

2900 | 3 | 40 |

| 40-250(I) |

8.8 12.5 16.3 |

81.2 80 77.5 |

2900 | 11 | 40 |

| 40-250(I)A |

8.2 11.6 15.2 |

71.0 70 68 |

2900 | 7.5 | 40 |

| 40-250(I)B |

7.6 10.8 14 |

61.4 60 58 |

2900 | 5.5 | 40 |

Contact Person: Sarah

Tel: 008613676018543