Product Details:

Payment & Shipping Terms:

|

| Product Name: | Air Operated Diaphragm Pump | Structure: | Diaphragm Pump |

|---|---|---|---|

| Power: | Pneumatic | Feature: | High Efficiency |

| Type: | Diaphragm | Warranty: | One Year |

| High Light: | double diaphragm pump,electric diaphragm pump |

||

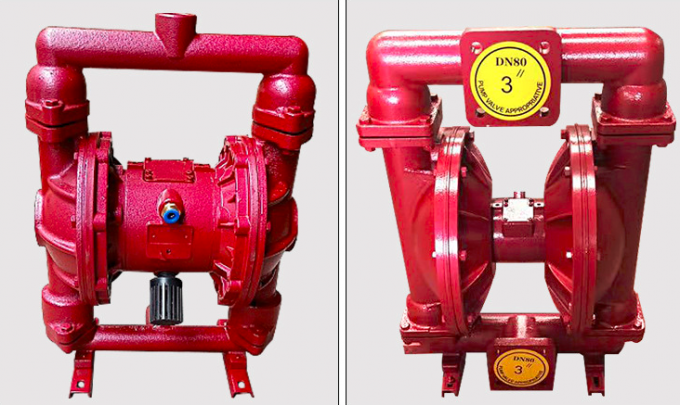

QBY Series High Pressure Pneumatic Diaphragm Pump Stainless Steel Zero Leaking Diaphragm Pump

Pneumatic Diaphragm Pump

Pneumatic diaphragm pump is the one of the most innovative pump.Using compressed air as power source, for all kinds of corrosive liquid, with particles of liquid, high viscosity, volatile, flammable, poisonous liquid, it can be smoked light.

Product Use

Technical parameters:

| Model | Dia(mm) | Flow (m3/h) |

Head (m) |

Suction (m) |

Max Particle Size φ(mm) |

Air Pressure (kgf/cm2) |

| QBY-10 | 10 | 0.8 | 50 | 5 | 1 | 2-7 |

| QBY-15 | 15 | 1 | 50 | 5 | 1 | 2-7 |

| QBY-25 | 25 | 2.4 | 50 | 7 | 2.5 | 2-7 |

| QBY-40 | 40 | 8 | 50 | 7 | 4.5 | 2-7 |

| QBY-50 | 50 | 12 | 50 | 7 | 8 | 2-7 |

| QBY-65 | 65 | 16 | 50 | 7 | 8 | 2-7 |

| QBY-80 | 80 | 24 | 50 | 7 | 10 | 2-7 |

| QBY-100 | 100 | 30 | 50 | 7 | 10 | 2-7 |

FAQ:

Q1. Fluid flowing from the exhaust outlet

A1. Check the diaphragm for any damage.

Check the diaphragm screw for looseness.

Q2. Air bubbles in the outlet fluid

A2. Check the suction pipe connection for good sealing.

Check the connection between the suction pipe and the intake manifold for good sealing.

Check the O ring between the intake manifold and the fluid cap.

Check the diaphragm screws for looseness.

Q3. Low pump output

A3. Check the air supply is stable.

Check the inlet/ outlet for any blockage.

Check connectors connecting the intake manifold for air tightness.

Check that the ball is not stuck to the seat or the ball is not improperly seated.

Q4. Air flows from the side gap of the muffler cover when there is no reciprocating

movement

A4. Check seal ring on slid valve.

Check seal ring on trigger rod.

Check seal ring on diaphragm link rod.

Q5. When the Teflon pump extracts paint, its diaphragm will wear due to long-term use.

The flow of the pump will become small after the diaphragm is changed.

A5. It is recommended to change the backup diaphragm beside the air chamber.

Q6. When the pump is used to draw the liquid containing a lot of sharp particles, the

Teflon diaphragm is easy to wear. Teflon diaphragm is provided with the advantage

of resistance to strong acid and alkali

A6. If the PH value is neutral, it is better to make use of wear-resistant diaphragm.

Q7. When the stainless steel pump is used to extract copper chloride + hydrochloride

solution, it will produce "pitting" effect under the function of chloride ions. This is

the currently main killer endangering the service life of stainless steel.

A7. It is suggested to make use of the pure PP pump.

Q8. The Y cup of air chamber in the pump easily wears, which causes the serious

accumulation of dust.

A8. It is recommended to increase three sources at the air inlet of pump.

Q9. If the outside diaphragm is damaged or the damaged diaphragm is not cleaned up

after replaced by the new one, the long-term contact between the backup diaphragm

and the paint will lead to deformation and shrinkage.

A9. It is recommended to replace the backup diaphragm beside the air chamber.

Contact Person: Sarah

Tel: 008613676018543